You’ve got your torch, propane, and concentrator – but that flame isn’t behaving like you know it should. Your oxygen supply is lacking but you’re not quite sure what’s wrong. Having the right oxygen supply is not only helpful, it’s absolutely required for the longevity of your torch face.

This situation is all to familiar, particularly to flameworkers who transition from a small torch and oxycon setup, to a larger torch.

“What works with a small torch, often leaves something to be desired on a larger burner.”

It’s a simple matter of geometry. A larger torch face has more openings and so requires more flow to produce the same flame velocity and characteristics. This important contributing factor to productive and efficient lampwork is what our core offering of oxygen technology products aim to fix.

Small Torches, Small Studios, and Small Budgets

With small torches, studios and budgets, there are not a whole lot of available options for the lampworker – but you’re in a much better position than a lampworker with a large torch, or studio and a small budget. You can melt boro and soft glass with just a concentrator if you operate a torch that consumes a small volume of O2 per minute.

If you’re running a small torch (more on that below) you can often build a working oxygen system around one or two oxygen concentrators. Concentrators usually come in 5, and 10 liter per minute models. Often times, jewelers and bead makers are able to use a single 5 or 10 LPM machine to run their torch. Just make sure to leave the oxygen valve on your torch cracked to provide an outlet for the oxygen concentrator, ensuring O2 purity stays high.

You can skip leaving your O2 valve open if you have our Adjustable Pressure Relief Vent installed between your concentrator and torch.

Concentrators are usually configured to output a pressure of 4-10psi, depending on the make and model. Some specialty machines, like our Stage 1 – 10 LPM Oxygen Concentrator are capable of output pressures of up to 20psi.

We’ll delve into why higher pressure and flow translate into more control behind the torch later on in this article.

Torches and Flow Rates

Selecting the right concentrator can be tricky, and not all concentrators produce the same amount or pressure of oxygen. A good starting point is our chart of torch specifications available here:

Once you know your torch O2 consumption and it’s upper limits, you can begin to select the components of your O2 generation system.

Why Run Higher Pressures?

Simply put, higher pressure means higher fidelity of flame control. When we put higher pressures, and in turn higher flow rates behind a valve it increases the range of pressures and flows available to the torch.

Increasing flow and pressure will make the needle valve knobs of a torch feel much more sensitive, and what would have previously taken several turns of the knob will now be a fraction of a turn. Think of it like going from a sluggish old beater, to driving a speedy and responsive sports car – reaction and performance are hardly comparable. Pedal to the medal actually gets you somewhere when you have the performance to match.

How to boost the pressure of an Oxygen Concentrator – Zero Cost Option

Most concentrators have an internal regulator that is turned down to a pressure that makes the device safe for use in a therapeutic or medical setting. We aren’t using these machines with that intent, and so boosting output pressure to more than double for no additional expense (besides labour) is a great idea for lampworkers.

To do this, you will need to open the case of the device to gain access to the internal regulator.

On the Stage 1, this is done by removing four Phillips head screws from the bottom of the machine and lifting off the plastic shell. Once inside, you’ll find the devices accumulator and the attached regulator.

Insert a 6mm hex wrench into the set screw in the bottom of the devices regulator and turn the screw clockwise, sending it inwards. Turning this screw all the way in will bring the outlet pressure of the concentrator up to 18-20 psi.

This simple fix is often enough to meet the demands of a small torch setup. If you’re looking for more, we have two more low-cost O2 system improvements before we get into fully managed intelligent Oxygen Systems.

Simple Tricks to Add Ease to Your Torch Workflow

As we mentioned earlier in this article, adding an adjustable vent to your oxygen delivery system can simplify your experience behind the torch. Allowing you to fully close the valves of your torch, the adjustable vent will allow your system to accumulate O2 and some pressure before allowing excess to bleed off to atmosphere.

By pairing a vent assembly and a small holding tank, users of a small torch can benefit from boosted and stabilized supply of O2 at their torch.

Still not enough Oxygen?

The next logical step is to increase the storage capacity for your low-pressure accumulation system. More storage is equal to a larger headstart in the race against a dwindling supply when a torch draws more O2 per minute is being produced.

If increasing storage and pressure to 20 psi still aren’t enough, that is where high flow systems like the Stage 2 Compression System come into studio design.

Compressors – High Flow or High Pressure?

The natural answer to the limitations presented by an oxygen concentrator is a second stage of compression.

There are a few options when it comes to compressing oxygen; and not just any air compressor will do. We require oil-free air compressors to boost the pressure of the oxygen in our systems.

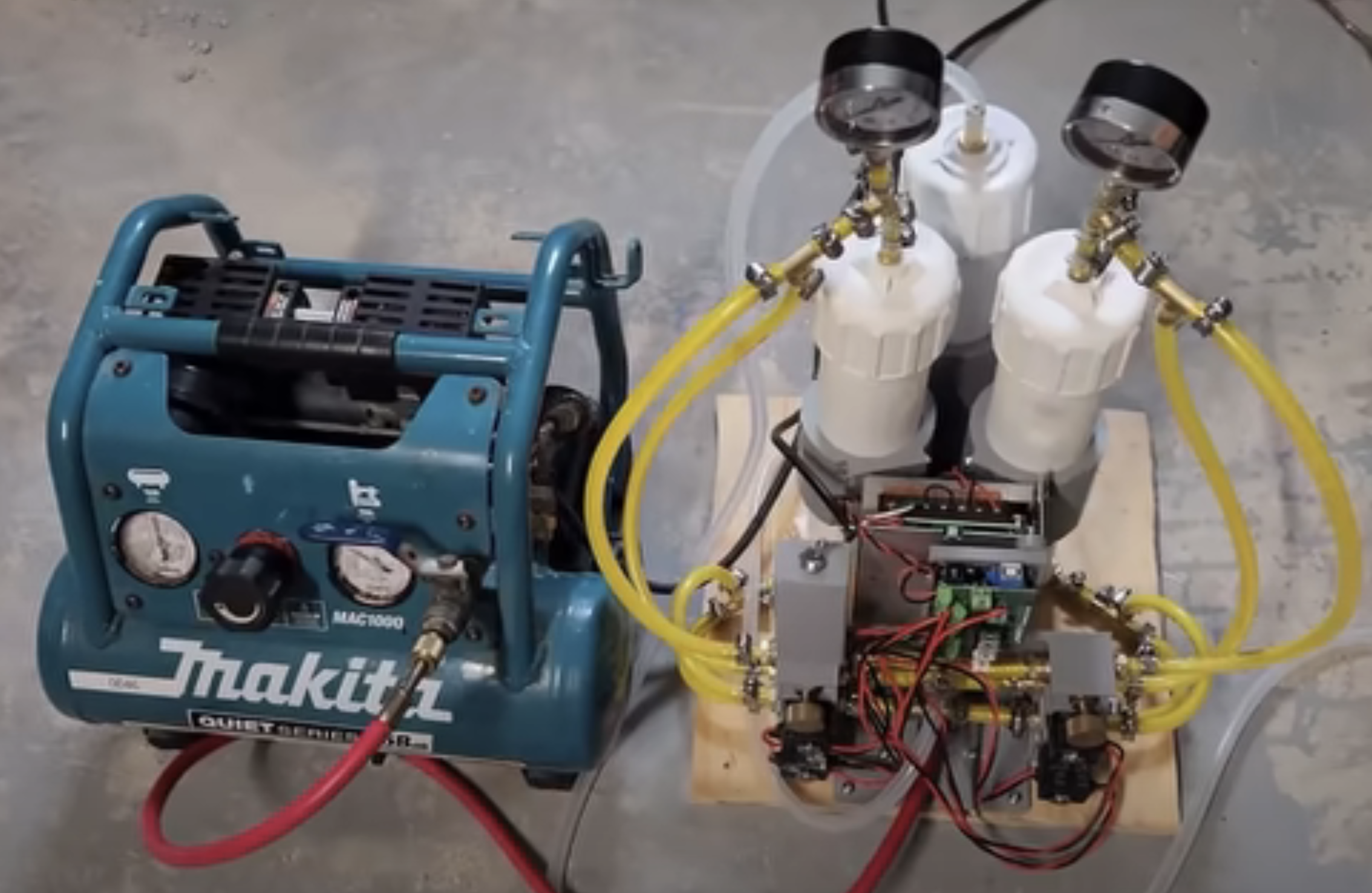

Many folks choose to DIY their systems, with plans and parts available in online groups, youtube videos and blog posts.

Others use low flow rate, high pressure systems made for the medical industry called homefills. Both can work, but there is a superior system available for lampworkers.

Stage 2 Compression Controller and Oxygen Management System

Some torches can get by on 20PSI and 10 or 20 LPM, but most boro lampworkers and hot shops simply cannot generate enough heat in a moment when limited by supply figures like that.

In a production shop, we typically see line pressures of around 100 PSI and torch delivery pressures up to 65 PSI for Oxygen. Averages at 15-35 PSI for most torches are still above the pressure range that standard oxygen concentrators can deliver.

Our Stage 2 systems can deliver the flow rates and pressures of a high demand glass studio. With a whisper quiet compressor delivering 105 PSI line pressure, and managing up to 8.0 liters per minute of production – the Stage 2 is the simple solution to boosting oxygen flow and pressure.

Most hobbyist lampworkers don’t need the production volumes made possible by our Pro model, which is why we offer the Duo and Solo models. These more affordable models deliver the same boosted pressure, without as much control or delivery capability. Simpler setups for less demanding applications.