Your cart is currently empty!

Category: Videos

-

DIY Oxygen Concentrator Projects with Open-Source Designs

Watch How A DIY Oxygen Concentrator is Made

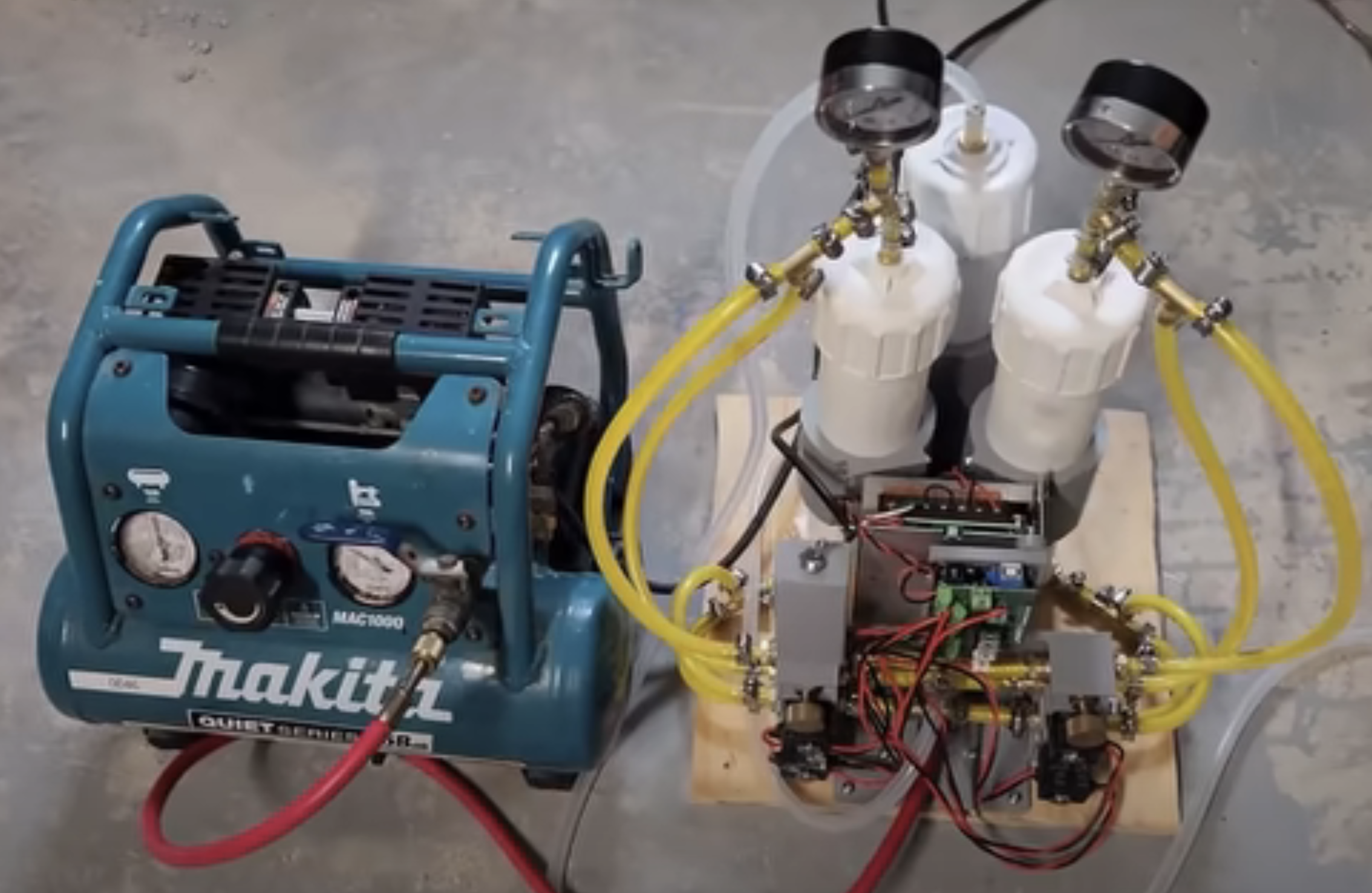

If you’ve ever wanted to understand how a PSA-based oxygen concentrator works — or even build one yourself — the above videos offer clear, step-by-step examples. This is more than a DIY tutorial: it’s a working blueprint for builders, technicians, and system designers who want insight into how oxygen generation systems are put together.

Hyperspace Pirate’s video covers another approach to at home Oxygen Concentration. We sent him some Zeolite to complete his project and were impressed with his home made machine.

How the PSA Process Separates Oxygen

The system uses Pressure Swing Adsorption (PSA) — the same core principle used in many commercial oxygen generators. Here’s the process simplified:

Step Process What Happens 1 Pressurize air Ambient air (≈ 78% N₂, 21% O₂) is fed into the system. 2 Nitrogen adsorption Zeolite in the sieve bed traps nitrogen molecules at pressure. 3 Depressurization Releasing pressure purges nitrogen from the bed. 4 Bed cycling One sieve bed absorbs while the other regenerates, providing continuous O₂ flow. “With PSA, you don’t create oxygen — you isolate and concentrate it. The smarter your cycle timing and air prep, the cleaner your product gas.”

Oxikit video, 7:15Core Components of the Build

Component Purpose Upgrade Tip Air compressor Pressurizes ambient air Use oil-free or filter downstream Condenser coil Cools compressed air Stainless steel improves durability Coalescing filter Removes oil/moisture Essential for protecting sieve beds Desiccant dryer Removes humidity Inline cartridges are easy to replace Solenoid valves Controls flow timing Look for high cycle life ratings PVC sieve beds Holds zeolite Proper packing = better performance Control system Manages cycles PLC or microcontroller options Explore compressors, filters, and valves at DPG Supply to match this DIY build with tested components.

This doesn’t work with a single sieve bed – dual sieve beds required!

- Dual sieves provide continuous oxygen output with minimal drawbacks.

“Many commercial PSA systems use two or more beds to balance flow and purity. This design mirrors that logic on a smaller scale.”

Talk to DPG Supply about control valves, check valves, and automation modules to fine-tune your cycle timing.

Pro Tips for Reliable Operation

- Dry air is essential — moisture will degrade your zeolite quickly.

- Stable pressure = stable purity. Avoid compressor fluctuations.

- Control your purge cycle to conserve energy.

- Use high-quality fittings to reduce leaks and maintenance issues.

Parameter DIY Target Notes Pressure 15–25 psi Higher pressure improves adsorption but requires better sealing Zeolite type 13X or LiX Impacts purity and cycle time O₂ purity 85–95% Dependent on flow rate and timing Looking to do something similar to this design? Check out DPG Supply’s concentrator components and parts.

If an off-the-shelf oxygen concentrator solution is more your style, check out the Stage 1 Oxygen Generator.

Disclaimer: This DIY oxygen concentrator design is for educational and non-medical use. For medical-grade oxygen delivery, consult certified equipment suppliers and follow regulatory requirements.