Your cart is currently empty!

Author: Dylan McFadden

-

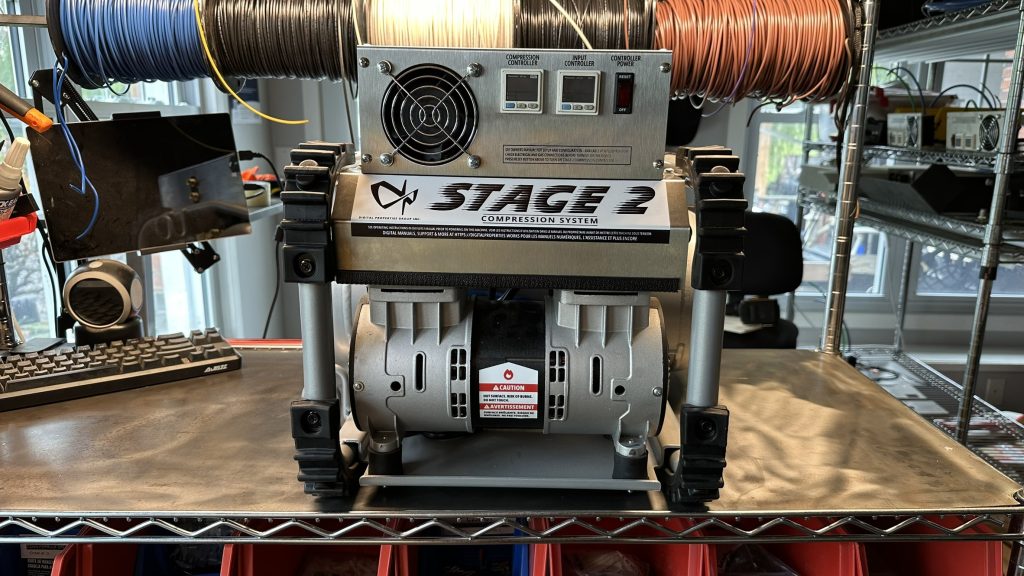

Scaling Challenges and Sustainable Solutions in Stage 2 ETL Certification

As we continue refining our machines and processes, the recent ETL inspection of our Stage 2 unit reminded us of two important truths: scaling up comes with greater complexity, and every challenge is an opportunity to reaffirm our commitment to sustainability.

Scaling Up Means Scaling the Risks

When production moves from single units to batch manufacturing, the stakes rise accordingly. A minor adjustment at a small scale can become a significant disruption when applied across multiple machines.

During our inspection, it became necessary to relocate two grounds within the Stage 2 machine. While the task itself was straightforward, the implications were not. To accommodate the changes, every power cord needed to be shortened and re-terminated. Across five machines, that meant 45 individual wires with crimped connectors had to be reworked. What could have been a simple adjustment in a prototype environment became a complex, time-consuming process at production scale.

This experience highlights a reality that any manufacturing team faces: scaling magnifies both the risks and the remedies. What matters is how you handle those challenges.

Commitment to Low-Waste Solutions

For us, the answer lies in smart design and sustainable thinking. Although the rework created 45 shortened wires with connectors already attached, none of that material will go to waste. That’s not by chance—it’s by design.

From the start, we’ve standardized our machines to use common connector types throughout. This means that the wires and connectors we removed can be reused seamlessly in other areas of future units. Instead of becoming scrap, every piece will find a new purpose.

Different Types of Quick-Connect Spade Receptacles Used in a Stage 2 By taking this approach, we not only reduce waste but also reaffirm our broader commitment to an eco-friendly, low-waste manufacturing process. The lesson here is simple: thoughtful design doesn’t just improve performance—it ensures sustainability is built into every step.

Looking Ahead

This ETL inspection tested our ability to adapt under pressure, but it also reinforced the values that guide our work. Scaling production will always introduce challenges, but by combining technical rigor with sustainable design, we’re proving that setbacks can be turned into opportunities for innovation and responsibility.

-

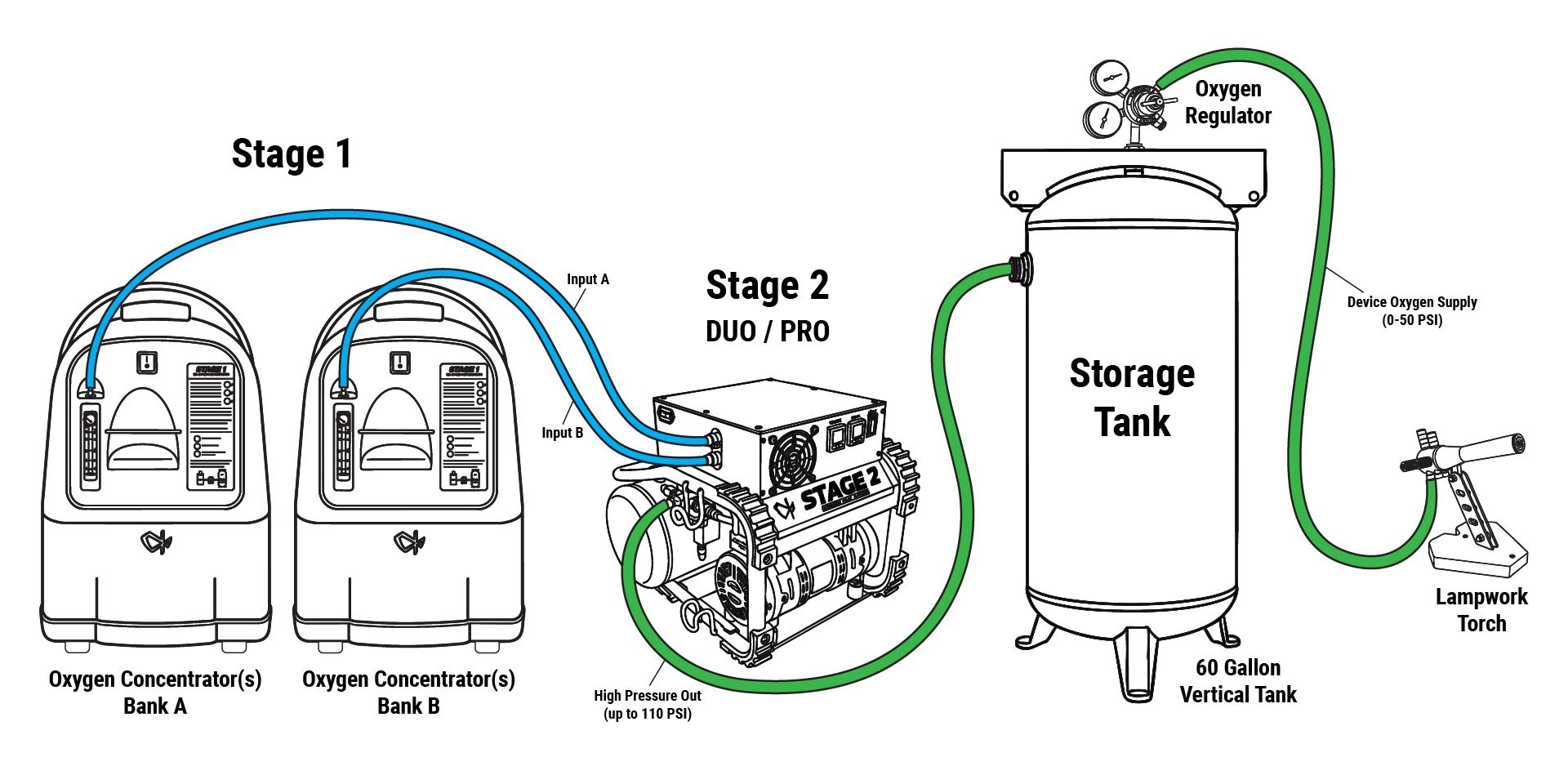

Designing for Durability: Why PTC Fittings and TPU Tubing Outperform Under Pressure

Oxygen compression systems demand reliability. Heat, vibration, and continuous operation can quickly expose the weaknesses of traditional hose clamps or barbed fittings. The result? Leaks, inefficiencies, and safety risks.

A better solution is pairing TPU (Thermoplastic Polyurethane) tubing with Push-to-Connect (PTC) fittings. This combination delivers strength, stability, and ease of use. Exactly what oxygen systems need.

Secure Under Stress

Unlike rigid materials that can loosen or crack, TPU is flexible yet durable, absorbing vibration without losing form. Paired with PTC fittings—which lock the tubing in place with precision seals—connections remain tight and reliable. Even in high-vibration environments, this setup resists leaks and fitting fatigue.

TPU Tubes 1/4″

Built for Heat

Continuous operation means elevated temperatures, and TPU handles heat far better than PVC. It maintains elasticity up to around 80°C, while quality PTC fittings are rated for similar or higher ranges. Together, they provide consistent performance where other tubing-fittings systems often fail.

Clean, Leak-Free Operation

PTC fittings use internal O-rings that seal firmly against TPU’s surface. This eliminates oxygen loss, protects system efficiency, and ensures safety. For oxygen-rich environments, clean, leak-free connections are non-negotiable—and this pairing delivers.

Fast, Simple, Reliable

No clamps, no tools, no complicated setup. PTC fittings connect in seconds and release just as easily for maintenance. TPU tubing complements this with flexibility and durability, making the system not only reliable but also efficient to service.

The Bottom Line

For oxygen systems under constant demand, PTC fittings and TPU tubing offer the perfect balance of:

- Long-term durability

- Leak-resistant performance

- Heat and vibration resilience

- Quick, tool-free installation

- Oxygen-safe materials

Whether your setup is stationary or mobile, this combination provides dependable performance with minimal maintenance—so your system stays focused on what it was built to do.

Need help selecting the right PTC fittings and TPU tubing for your system? Our team offers expert guidance and a full range of compatible components to meet your application’s needs.