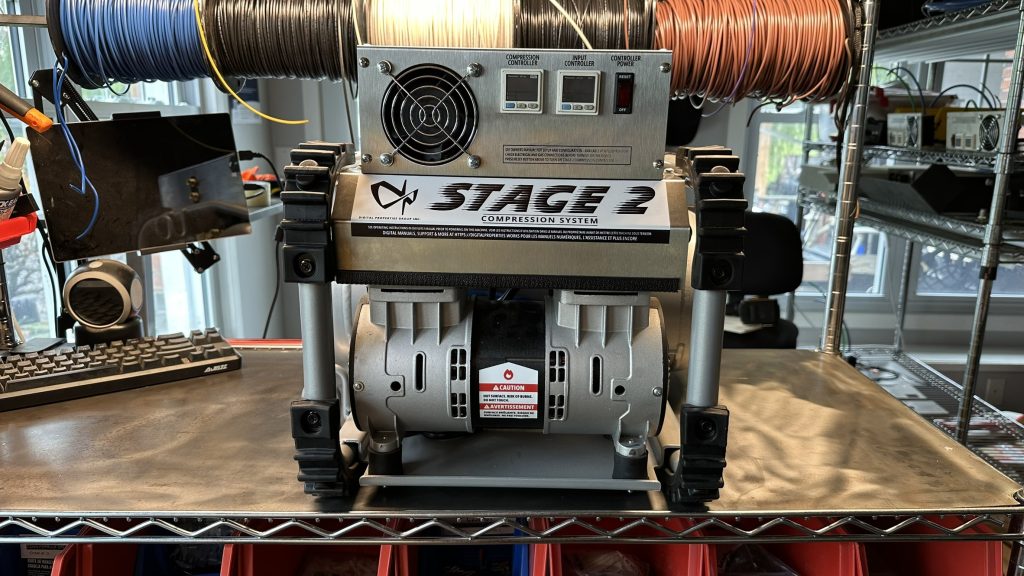

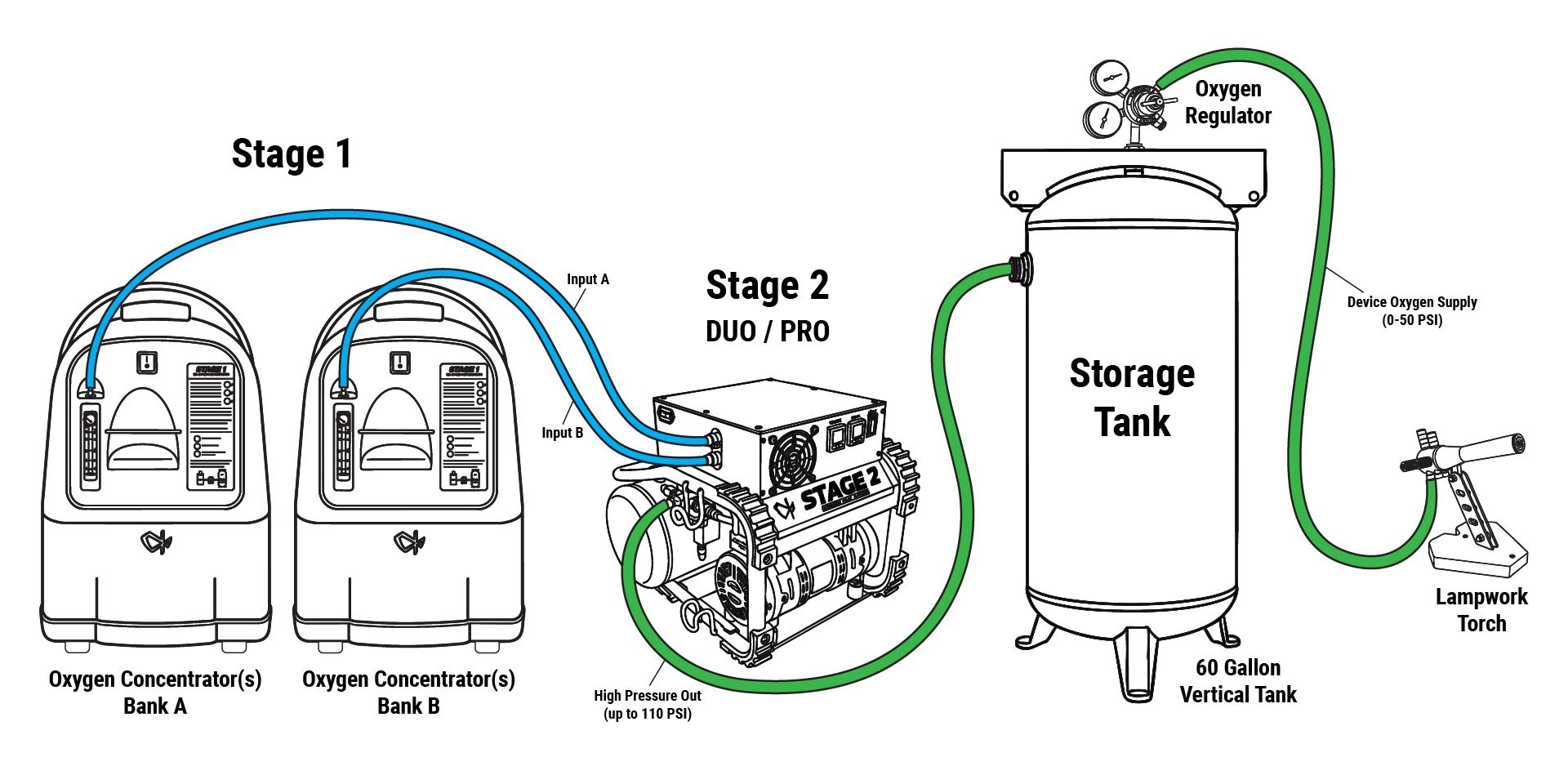

My journey as a lampworker—and eventually the creation of Dylan Chris Glass—began in an unconventional way. I never once cracked open a tank of oxygen. From the very start, I built a DIY oxygen compression and control system based on an early Stage 2 prototype. That decision changed everything about how I learned, created, and grew as an artist..

Breaking Free from the Oxygen Tank

For many glassblowers, oxygen is one of the steepest recurring costs of the craft. A single K tank might only last a day at the torch, and refills can run over $70 each. Imagine trying to hone your skills or experiment creatively while watching those costs stack up day after day. It’s stressful, and it forces artists to ration their torch time.

I never had to face that pressure. I didn’t need to count hours, worry about deliveries, or compromise my learning. Instead of carefully budgeting my time, I could fully invest it into my craft.

Unlimited Time at the Torch

Because my oxygen supply was functionally endless, I spent days on end practicing with cheap clear glass, building muscle memory, and experimenting without hesitation.

“Every mistake became a lesson instead of an expensive setback. Every spark of inspiration could be followed instantly.” – Dylan Chris Glass

That freedom to explore gave me the confidence needed to accelerate my growth as an artist.

Creativity Without Limits

When you don’t have to weigh the cost of every flame, you take more risks. I pushed myself to try new techniques, test ambitious designs, and refine my skills relentlessly. That freedom nurtured my creativity and allowed me to develop a style that wasn’t held back by the fear of burning through expensive tanks.

The Business Advantage

This didn’t just impact my artistry—it shaped my business. For over three years I worked full-time at the torch, supported by generated oxygen alone. Without constant oxygen bills cutting into my margins, I could price my work competitively without undervaluing my time or effort. The consistency of having oxygen on demand made my workflow predictable, efficient, and profitable.

Always Ready for Inspiration

The best part? Inspiration doesn’t follow a schedule. Whether it’s early morning or late at night, with a Stage 2 system, oxygen is always ready. There’s no waiting on deliveries, no stress about running low—just freedom to create whenever the spark strikes.

In Conclusion

“By starting with generated oxygen instead of tanks, I gave myself the chance to focus entirely on the craft. And that freedom changed everything.” – Dylan Chris Glass

If you want to spend less time stressing about oxygen and more time building your skills and pushing your creativity, the Stage 2 System is the perfect addition to your studio!